The underestimated influences of electrical energy on the operating process!

The conditions of electrical energy supply have changed significantly in recent years and will continue to do so. What are these effects and how do they influence the supply of electrical energy in your company?

Other influences are the further advancing digitalization and networking through the Industry 4.0 movement. As well as energy-saving efforts, which call for greater use of automation technology and modern light sources, for example. The use of this same modern technology has changed the load on power grids compared to the past. On the other hand, these devices also have changed requirements on the electrical power supply.

In this article, we will address these and other issues and show you possibilities for a targeted approach and action. This will enable you to set the right course for the future of energy supply in your company.

The safe electrical power supply

What does the excellent quality electrical energy look like? Because actually the electricity comes from the socket and so it is good! Or is it not? Have you ever thought about how the quality of the electrical energy looks like or what kind of interferences are there?

Even if it looks first of all in such a way, as if the energy comes from the plug socket and one has here no influence on it like this happens, then also our electrical energy has different quality characteristics. First of all we have to seethe two things voltage and current, because what we get is not a current but a voltage. The current flow comes only by our devices to state, therefore we will speak in this article mainly of the voltage.

But what are these very quality characteristics? We expect that the mains voltage we are promised will also reach us. This means that we already have the first quality feature, our voltage level. In Europe, this is normally 230V or 400V in the low-voltage network. But is the voltage we measure at our socket really always exactly that high? Have you already thought about what the tolerance of +/-10% means for devices?

Another quality feature is the mains frequency. Since we are in an alternating current network, the mains voltage has a certain frequency. For us in Europe this mains frequency (partly also called power frequency) is 50Hz. Many devices orientate themselves on the mains frequency, e.g. to record the time or to control other internal functions.

The Ideal Electrical Power Supply

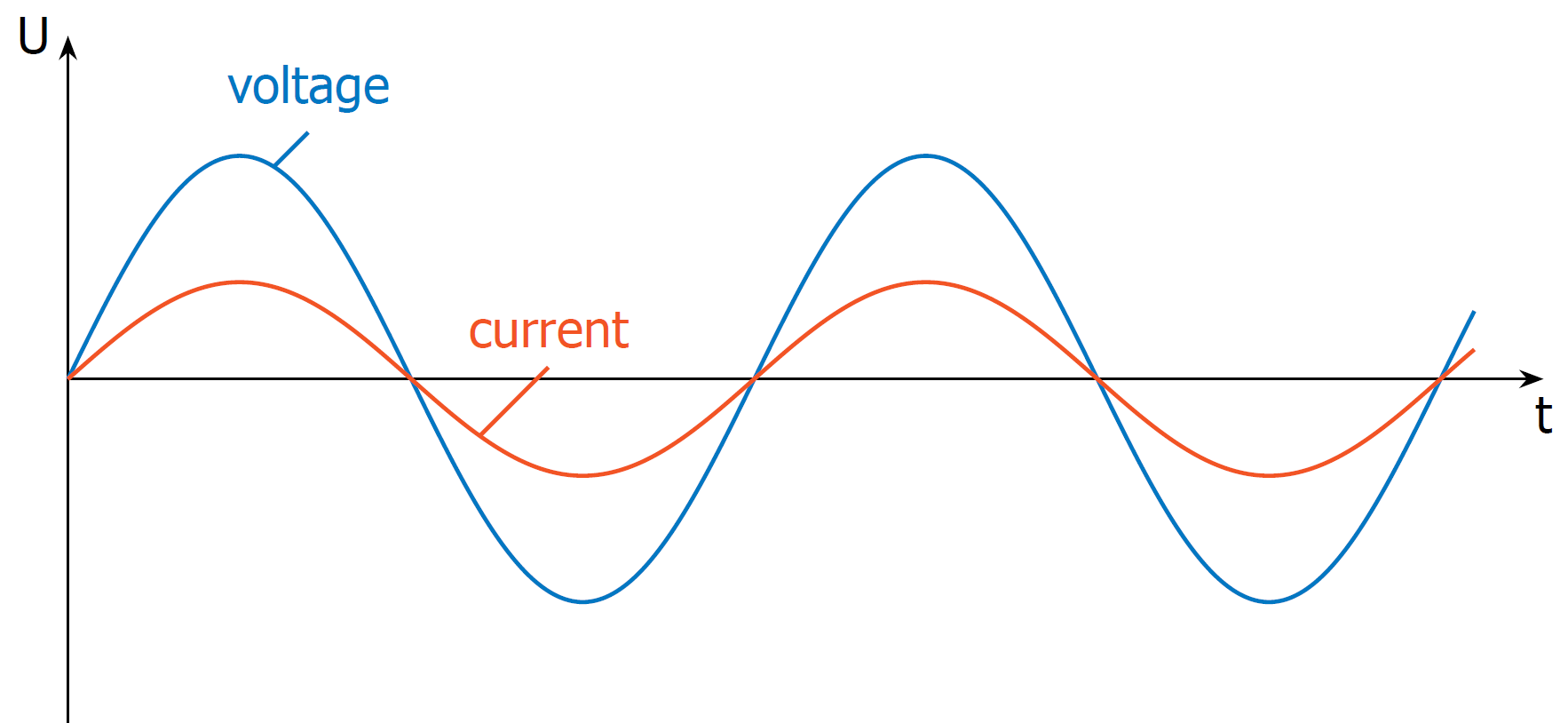

If we look at the mains voltage with an oscilloscope, it ideally looks like in Figure 1, where we can see that the mains voltage follows a sine wave. In addition, the frequency of the voltage corresponds to the energy frequency, which is 50Hz in Europe.

Figure 1: Current and voltage curve of a linear load

The real electrical power supply – voltage level

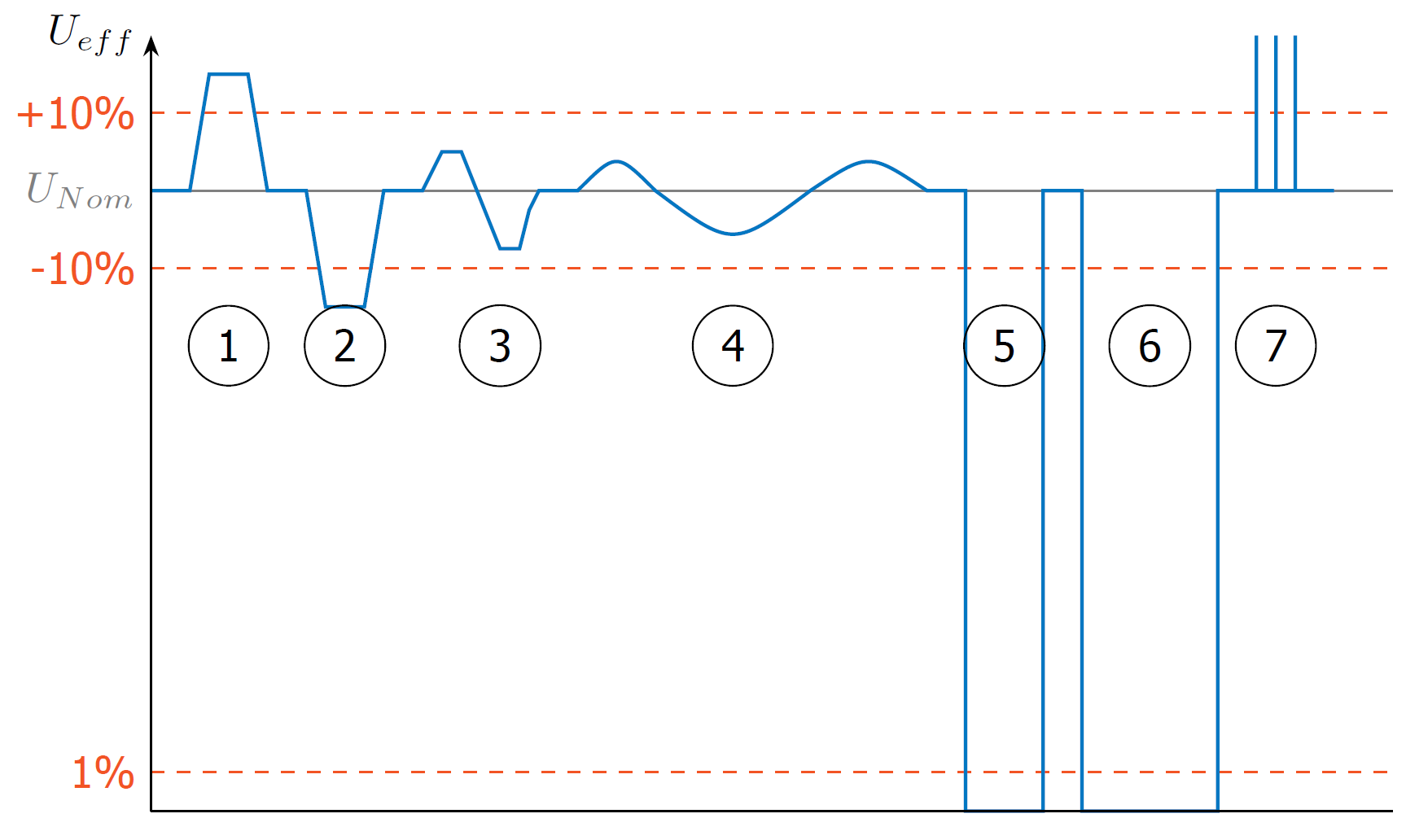

As you can certainly imagine, this “ideal mains voltage” shown above is not to be found in reality. The mains voltage deviates from the ideal supply due to various influences. The influences on the voltage level can be found as an overview in Figure 2. As a cause, very diverse influences can occur here, one of which we will explain in this article.

Figure 2: Overview of mains voltage disturbances

- Overvoltage

- Undervoltage

- Voltage fluctuations / voltage changes

- Flicker

- Short-term interruption (less than 3 minutes)

- Long-term interruption (more than 3 minutes)

- Transient overvoltage (duration approx. 1µs to 1ms)

The phenomena shown here cannot be prevented in the transmission of electrical energy. We can only ensure that these influences do not interfere too much or that devices are insensitive to them as far as possible. Sensitive to such influences are, for example, computers, control systems, switching power supplies, sound systems, lighting control systems, process technology and much more.

The real electrical power supply – mains frequency

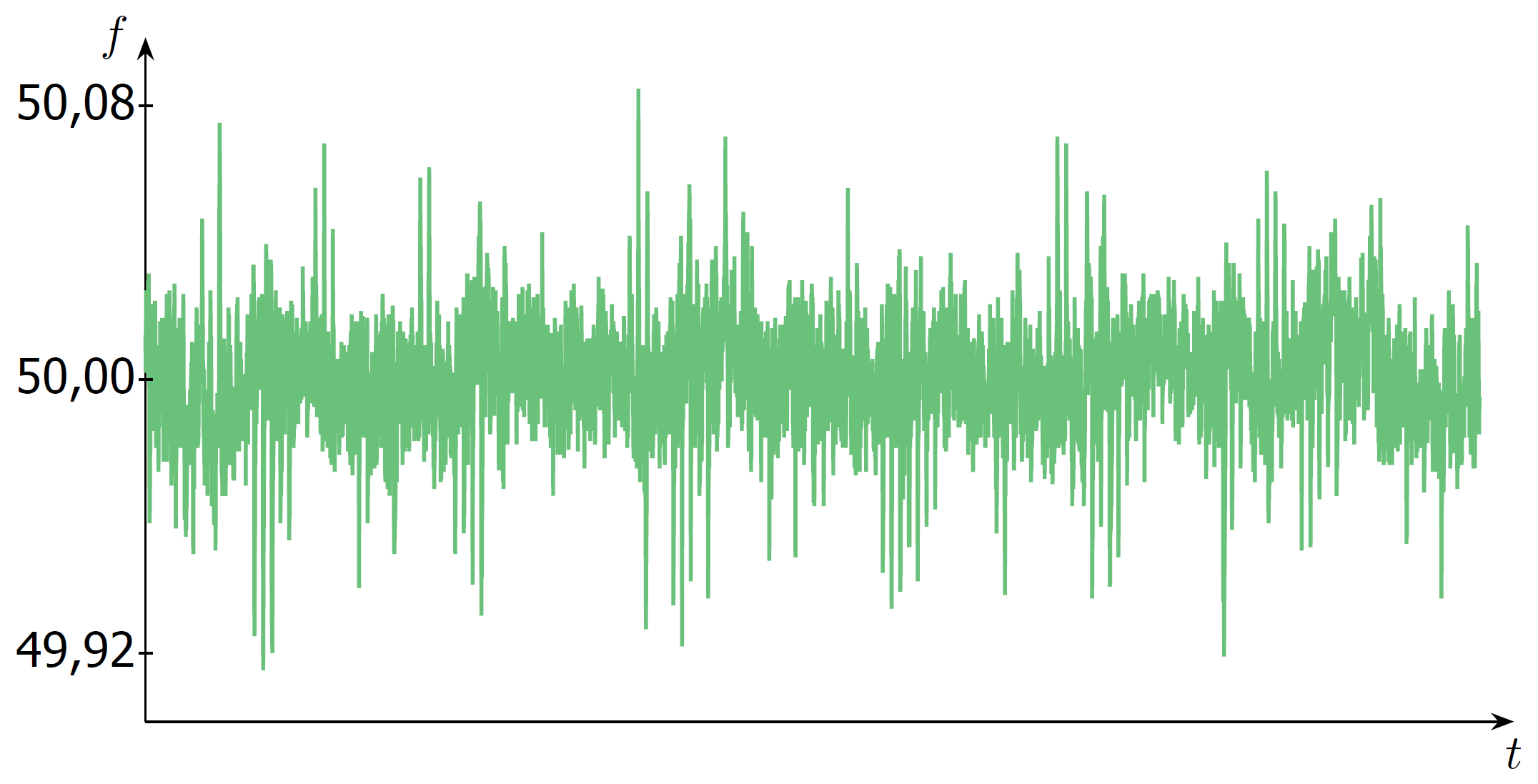

If we consider the mains frequency, this is also not always a constant 50 Hz, but is subject to diurnal and seasonal fluctuations. Figure 3 shows the course of the mains voltage over a period of six days. It can be clearly seen that the fluctuation range of the grid frequency is in the range of a few millihertz. This means that grid frequency disturbances are not to be expected on the European mainland. Exceptions are large-scale disturbances of the supply network, which occur extremely rarely.

Figure 3: Course of the grid frequency over several days

The real electric power supply – waveform

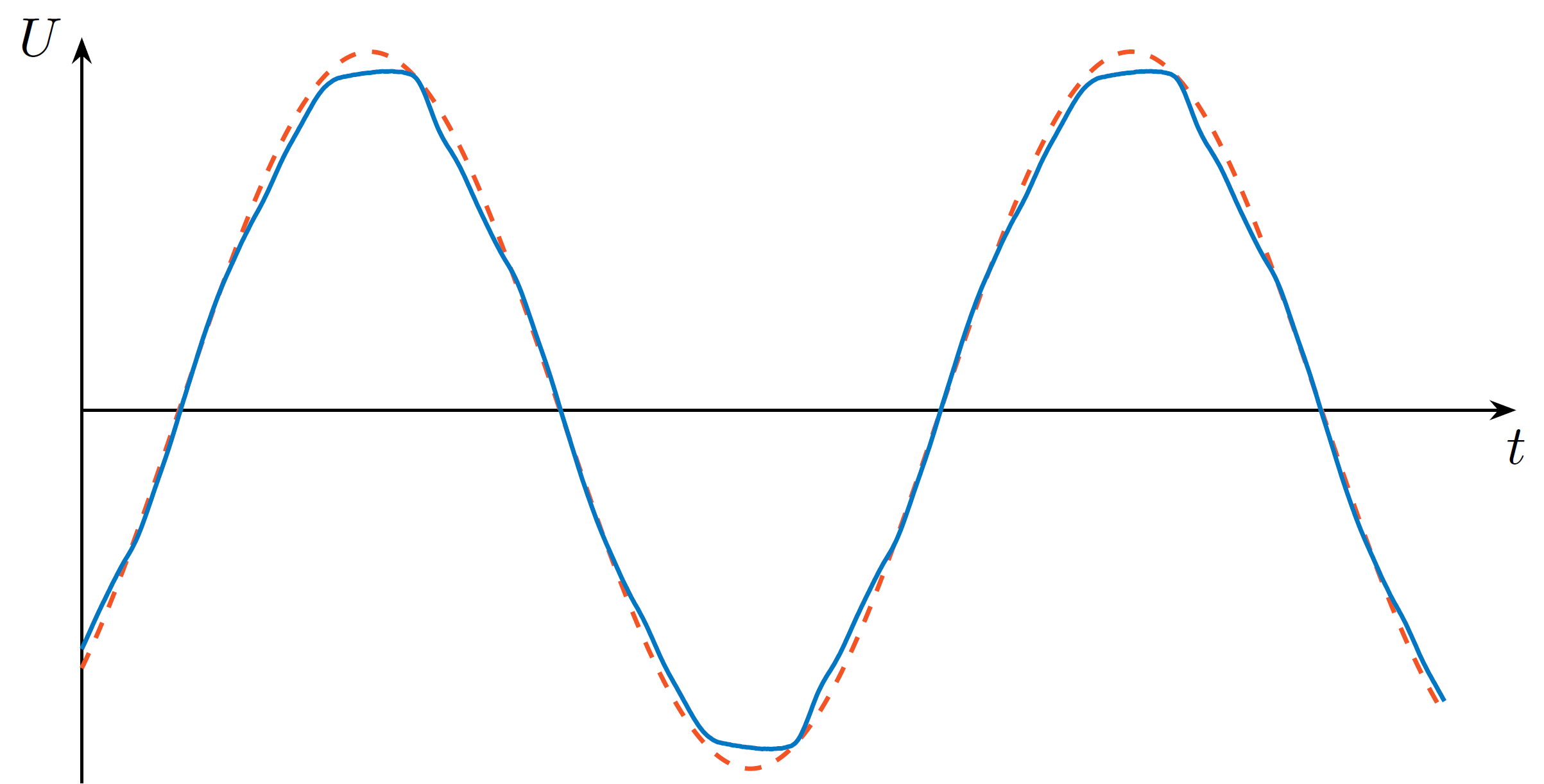

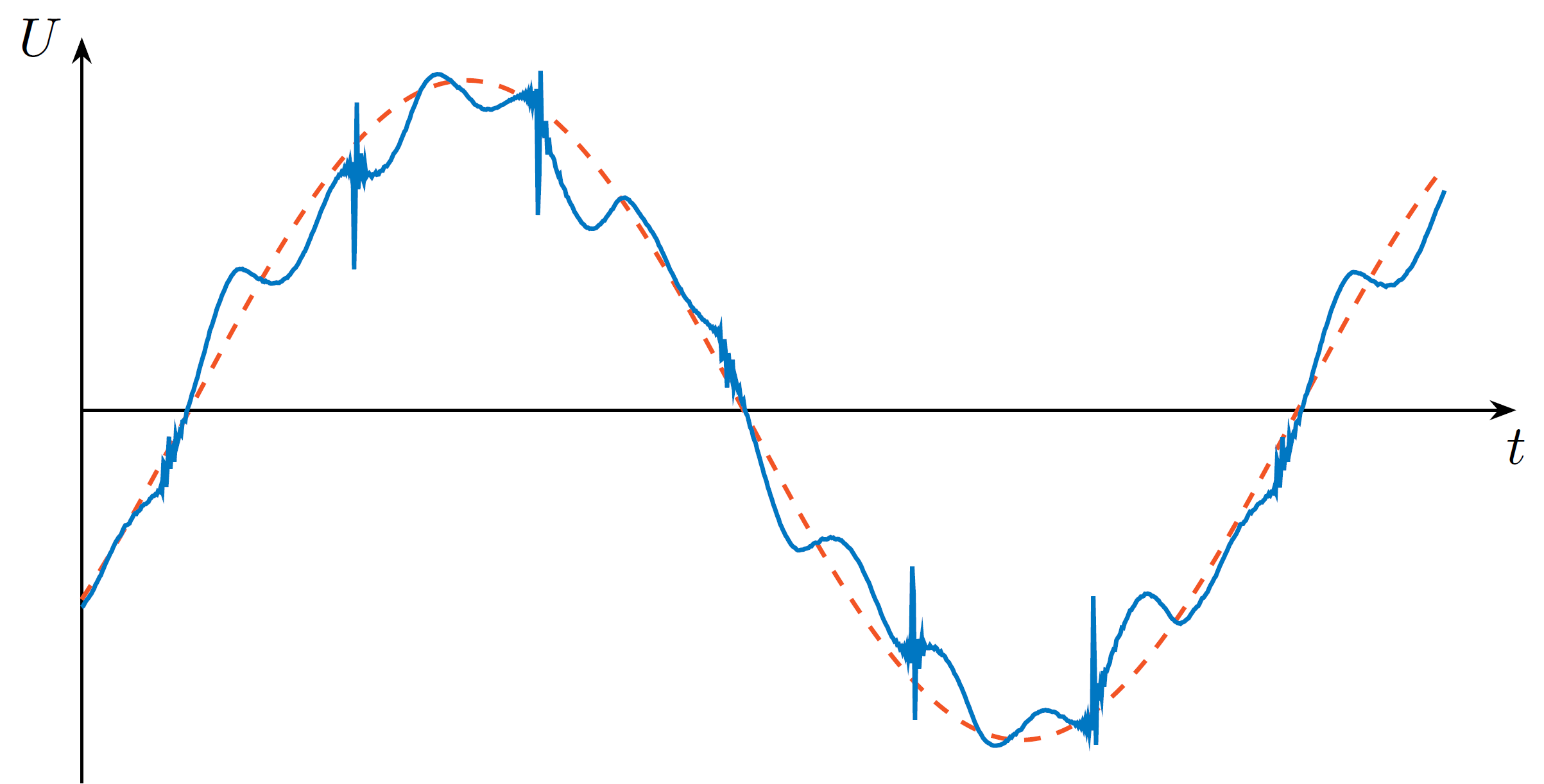

The last quality feature we looked at before with the ideal supply voltage is the sine wave itself. Unfortunately, in our power supply, this is also not as nice as previously shown in Figure 1. The sine wave is “dented” by various influences, as can be seen in Figure 4 compared to an ideal sine wave. These dents and dings, while not looking very bad, can already have a huge impact on the operational reliability of a plant. For a better comparison, an idealized sine wave is superimposed in dashed red.

Figure 4: Real mains voltage with idealized sine wave

In reality, however, the mains voltage can look much worse, as the example in Figure 5 shows. Here you can better imagine that this can lead to problems.

Figure 5: Highly distorted mains voltage with idealized sine wave

What is Power Quality?

All the above-mentioned phenomena are summarized under the term Power Quality, which means electrical energy quality. Therefore, this term describes a very wide field of independent phenomena. These also go beyond the phenomena described here. As a result, the individual terms are often mixed up in linguistic usage. Thus, harmonics are often used synonymously with power quality. Power quality, in turn, is a subfield of EMC (electromagnetic compatibility). These terms and their classification will be explained in a later article.

Since both the energy suppliers and the consumers are responsible for power quality, there are a large number of technical regulations and standards that specify limit values for this. These apply in each case to different situations and are, for example:

- VDE AR-N 4100 – VDE AR-N 4100 – Technical rules for the connection and operation of customer installations to the low voltage network (TAR low voltage)

- VDE AR-N 4105 – Generators connected to the low-voltage distribution network Technical requirements for the connection to and parallel operation with low-voltage distribution networks

-

VDE AR-N 4110 – Technical requirements for the connection and operation of customer installations to the medium voltage network (TAR medium voltage)

- EN 61000-2-2 – Compatibility levels for low-frequency conducted disturbances and signalling in public low-voltage power supply systems

- EN 61000-2-4 – Compatibility levels in industrial plants for low-frequency conducted disturbances

- IEEE 519 – IEEE Recommended Practice and Requirements for Harmonic Control in Electric Power Systems

- D-A-CH-CZ – Technical rules for the assessment of system perturbations

- EMV-ILA® – EMC Guidelines to achieve electromagnetic compatibility in the automotive plants

Mains disturbances of the own devices

Further repercussions on the electrical power supply are caused by the devices connected to the corresponding network section. This part of the network repercussions is the responsibility of each individual and can decide about a safe function of all devices, servers and production facilities. The feedback effects of one’s own devices on the power supply can be roughly divided into the following phenomena:

- Harmonics

- Flicker

- Switching frequencies

- fundamental reactive power

- Leakage currents

- EMC disturbances (conducted and radiated)

These repercussions of the own equipment are often very complex and require an intensive analysis to find the appropriate solution.

Are power system disturbances a curse of high-tech products?

What is now the cause of the disturbances in our supply voltage shown above? Energy-saving measures and modern electronic devices are significantly involved here. For this reason, mains distortion is often associated with high-tech products. However, this is not entirely correct, since classic devices also cause mains distortion, as we will look at below. What has changed, however, is the nature of the network distortions.

Causes of network disturbances

In order to illustrate possible causes of mains reactions, we would like to show this with two examples. The first example is a high-power motor without a frequency converter, i.e. operated directly from the mains, as was often the case in the past. The second example is a frequency converter as used in modern production plants.

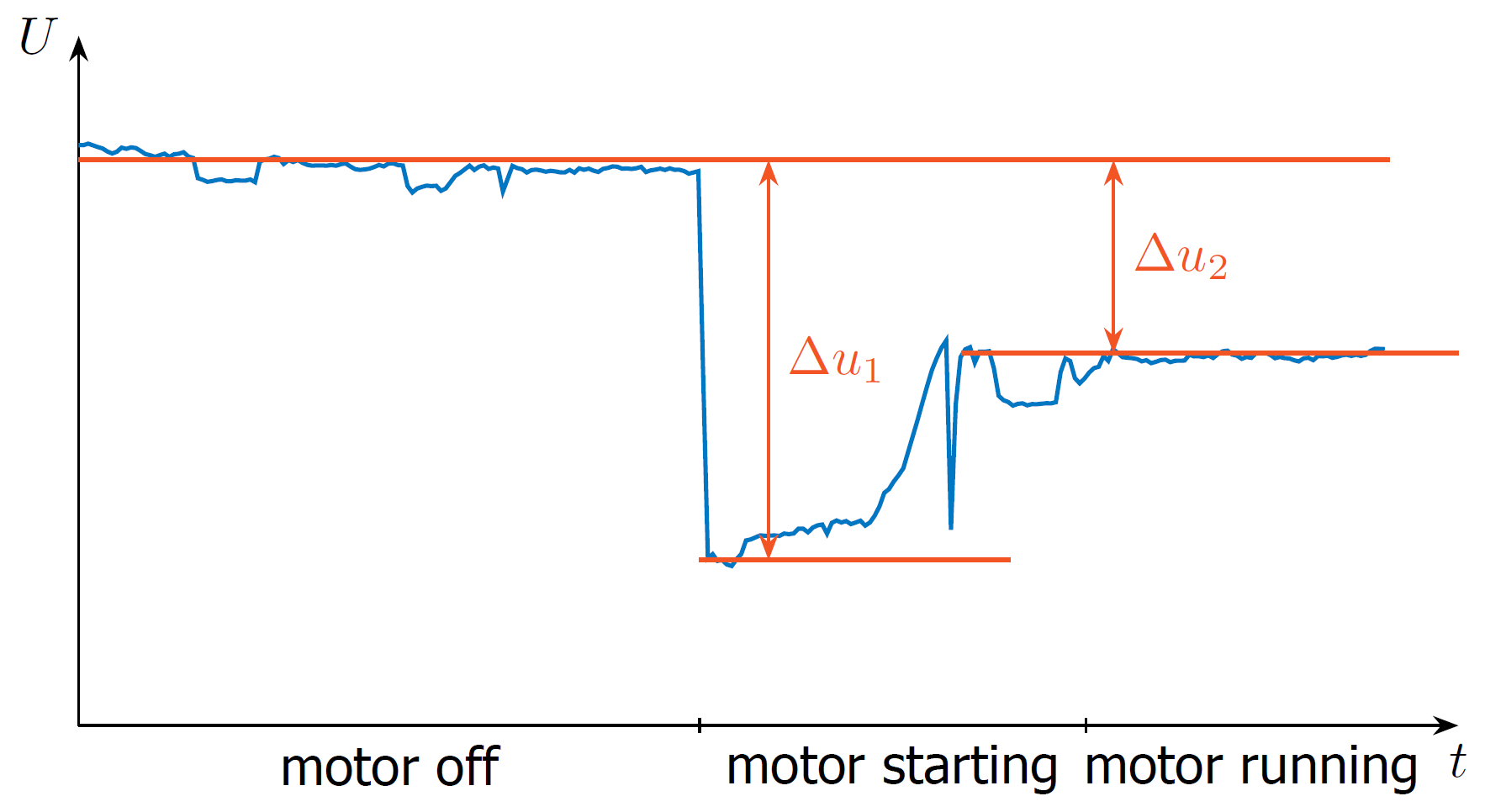

Let us first consider the asynchronous motor, which causes voltage dips due to its start-up behavior. These voltage dips, as shown in Figure 6, can be reduced to a practicable level by suitable measures. In most cases, soft starters help here, although it must also be borne in mind that these are electronic products. Although these limit the current drawn, they deform the current during the start-up process as shown in the following example with the frequency converter. This allows the voltage dip to be limited to Δu2.

Figure 6: Voltage dip due to startup of an asynchronous motor

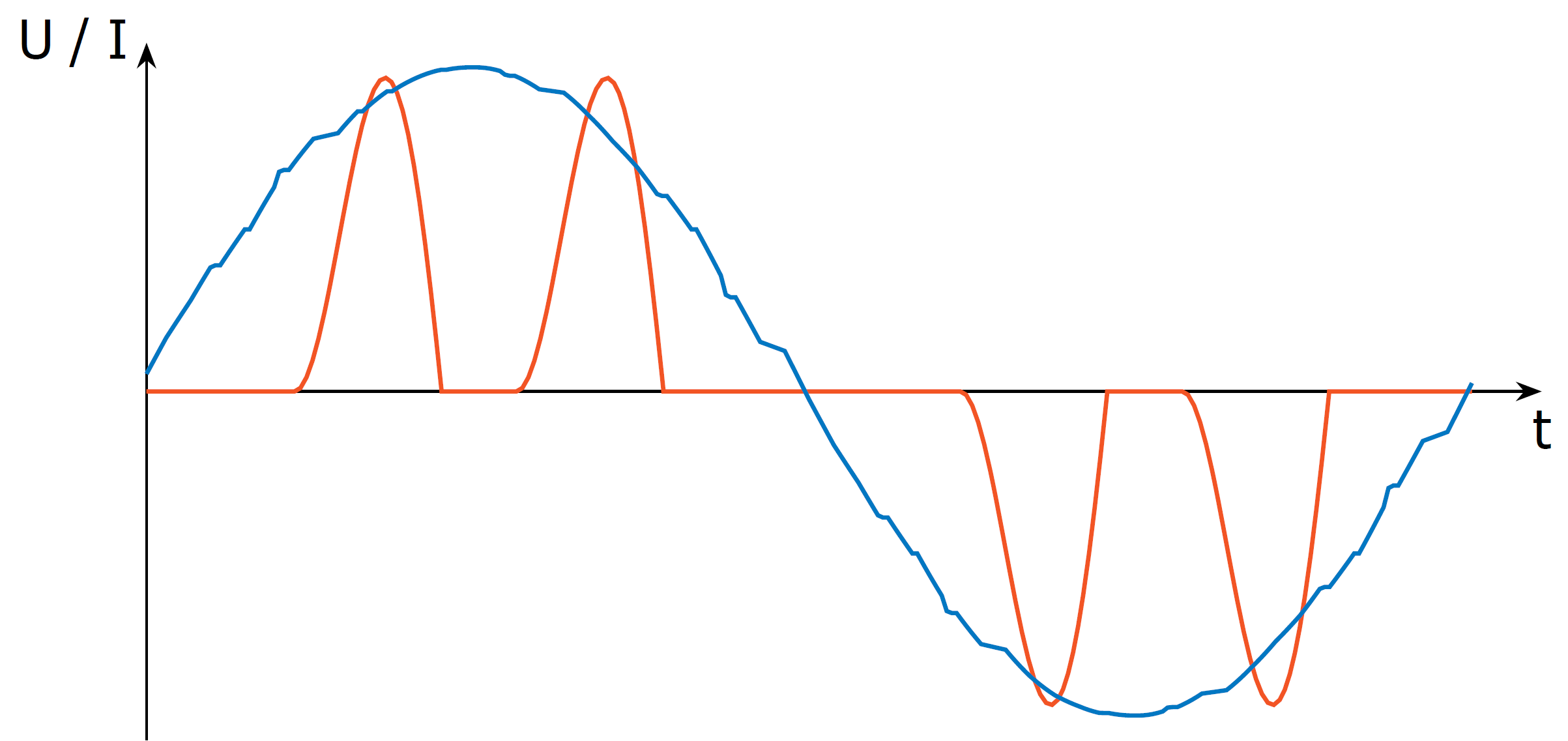

Let us now consider the frequency converter as a representative of electronic loads that we use in everyday life or in industrial processes. This is also supplied by the sinusoidal voltage. However, frequency converters, like other electronic devices, no longer draw sinusoidal current from the mains. Figure 7 shows an example of the current curve of a frequency inverter. It can be clearly seen that the current curve does not follow the sine of the mains voltage, as can be seen in Figure 1. This non-sinusoidal current consumption means that the mains voltage is also deflected from its sinusoidal shape, as shown in Figures 4 and 5.

Figure 7: Current flow of a simple voltage DC link converter

Avoidance of mains disturbances

It is advisable to consider very carefully how to effectively reduce the effect of the mains feedback already during the planning and arrangement of the devices and systems in one’s own power supply system. This means that the connection point or configuration of one or more devices can already set the course for improving or worsening the influence on the mains voltage quality. Even if devices are tested, this does not mean that they do not cause interference. It only means that these devices meet the minimum requirements.

However, if it is an existing equipment in the power system under consideration, then the possible measures are limited. But even this is not a reason to despair, then only the procedure is different. In any case, it is necessary and sensible to carry out a power quality measurement at various nodes in order to localize the critical points. The knowledge gained from the measurement results can then be used to determine an optimal solution. This usually involves the use of appropriate filter technologies, which can be retrofitted. We will go into this in more detail in a later article.

Whatever the technical solution ultimately looks like in implementation, it must be ensured that the operational processes are not jeopardized and that sporadic downtimes do not occur as a result. After all, production downtime always costs money and must therefore be avoided at all times.

The risk to employees must also not be lost from focus, as uncontrolled processes and defective machine parts can pose a great danger to life and limb.

Therefore you should have a good Power Quality

For the operator of a plant, or as the person responsible for the energy supply and operational safety in the company, a safe voltage supply has the following advantages:

- Production losses due to unplanned downtimes following defects in equipment are avoided

- Wear and tear on equipment is reduced to a minimum

- Maintenance costs are optimized

- The risk of overheating of electrical components is reduced and thus the risk of fire is reduced

- Faulty shutdowns of safety devices are avoided

- Costs for electrical energy can be reduced

- Minimization of investment costs and reduction of fixed costs

- Insurance premiums can be reduced

The responsibility for good power quality lies with …

… each company itself. Every company in Germany is responsible for complying with VDE AR-N 4100 and VDE AR-N 4110 (or other European regulations) on the basis of the technical connection conditions. In addition, most companies are their own energy supplier, which operates the low-voltage network and often also the medium-voltage network itself. This means that companies are responsible for ensuring that their equipment and systems can be operated safely. On the other hand, the operation must not disturb other customers and consumers connected to the public power grid.

In order to assess all this correctly and take the appropriate measures, a specialist department for in-house power supply is necessary.

How do you achieve good power quality in your operation?

So that the topic of “mains feedback” is no longer an issue in your company, you should deal with it at an early stage. We, the Ceno Power Quality GmbH, can support you in this and advise you accordingly, so that you can also be relaxed in the (power) grid. Simply get in touch with us via our contact form.

With Ceno …

… you can be sure that your network problems are a thing of the past.

…relaxed in the (electricity) grid

Thanks so much for talking about how different aspect of electrical supply has changed to make everything more efficient and cheaper. I have a friend who recently bought a small building to start a local shop in. She wants the place to look homey and welcoming so she’s been looking into finding an electricity provider so she can add fun lights all over the place.

I appreciate the detailed article and you sharing.

I appreciated it when you shared that it is best to consider very carefully how to efficiently overcome the effect of the mains feedback throughout the preparation and design of the devices and systems in one’s own power supply system. In this way, it help will ensure that the operation can be run smoothly. I would like to think if a company needs to work on an electrical project, it should consider getting the necessary equipment from a reliable supplier.